Figure 1. Oil-exploiting Valhall complex in Nothern Sea

BP Group called it “the first mover of future oil-rig”, and let it take the piorneer in applying modern technologies. The key renovation was that high-voltage direct current was used for distributing power to alternating current in offshore oil-rigs for the first time. Offshore gas turbines are to stop running for the entire productivity of 78 MW to be loaded 300 kilometers far away from Norwegian beach by high-voltage direct current Light technology of ABB.

Valhall complex has 5 oil-rigs in the sea connecting with each other by bridges. Among them, 3 oil-rigs are constructed 6 km far away from the main complex. Oil-rigs that are used for production and air compression as well as staff’s lives will be replaced with a new project as soon as they get acceptance from both PV’s partners and authorities.

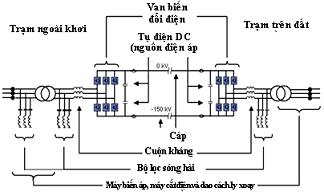

That new project together with Valhall complex will be supplied power from shore (PFS) via ABB’s HVDC Light power transmission system which applies the most advanced technology in productivity electronics and computer-processed control and protection system. The power transmission system includes both inshore and offshore power transformer stations connected with each other through 292 km of cables. The system transforms alternating current from Lista-based 300 kV Elkem transformer station into 150 kV direct current, conducts electricity through one-way undersea cables then transforms reversely into 11 kV alternating current in new oil-rigs.

Use of HVDC power for offshore works has been discussed for many years. However, as for traditional HVDC technology, an alternating system needs to be powerful enough to operate which remains unfeasible at the moment. The case has changed for 10 years when ABB conducted effectively the HVDC Light technology using transistors instead of thyristors of traditional HVDC technology. The technology can help new models of electricity transformers switch over by themselves meaning it need not an alternating voltage available for operation but allocating passively electricity to an additional charge.

That use of HVDC for offshore power transmission was first made in 2005, distributing power to new compressors in Troll A oilrig off the coast of Bergen city, Norway. The main difference between power distribution from mainland to Valhall complex offshore and that for Troll is that this is the first time a completed power system for the entire oilfield has been distributed by HVDC from the mainland.

Costs and emission to be lowered

It is both effective in costs and economical in space as well as offshore oilrig’s load to distribute power from the mainland.

For almost all of offshore construction works, generators and compressors are driven by gas turbines or diesel engines. Most of them have a low rate of productivity, approximately 20-25%, and as a result emit more carbon dioxide CO2 and consume unnecessarily a large amount of fuel.

Figure 2. Valhall complex will be supplied power from mainland by ABB’s HDVC Light

On the continental shelf of Norway, tax policy for CO2 emission has been effective. Price of emission is very high, even there is no markets for trading emission standard. If power is distributed from the mainland, emission of offshore equipments is no longer a matter of concern because it helps operators to minimize costs. Besides, inshore power transmission is beneficial in a way that it reduces cost of maintenance, lengthens equipment’s expectancy, and enhances availability of power distribution in comparison with gas turbines and diesel engines. If power transmission equipments can be installed to offshore construction works that are no longer in use delay of dismantling costs is essential. Moreover, it can reduce costs of greenhouse gas emission by employing inshore power generators which are more effective than that of offshore. Even, if power losses due to long power transmission distance from the mainland to offshore equipments are counted up to 10%, the amount of money of HVDC project to be saved remains significant in most cases.

As for Valhall work, when shifting to inshore power distribution to offshore platform equipments, it is estimated that each year will see a reduction of up to 300,000t CO2 and 250 t NOX compared to using directly a mixed-cycle power plant which utilizes gas turbines emissing NOX at a low rate.

Active control

With HVDC Light technology, use of serial capacity transistors helps to connect potential transformers to the electric network at levels of voltage that have not been done before. That use can be applied to power transmission, reactive power compensation, harmonic generating compensation or protection against flicker. The transistor, by “quick vector controlling method”, can control active power and requadrature power separately, suppress harmonic wave, even in weak-current network. Transformers are managed by a strong and durable HVDC control equipment namely Mach No.2 which has been experienced in many constructions works installing HVDC and SVC. Following HVDC Light technology, fundamental frequency is created by pulse width modulation (PWM).

When using PWM, amplitude and phase are automatically and nearly immediately monitored at certain limits which helps to control active and requadrature power independently and quickly. Therefore, potential transformer with pulse width modulation (PWM VSC) is an ideal part of power network. According to systematic view, the transformer acts as an engine or generator without inertia, controlling at the same time active and requadrature power. Besides, in case of short circuit, the transformer shares small part of this short-circuit capacity because of its ability to control alternating current (AC).

The only factor at terminals of transmission circuit that needs defining clearly is DC voltage, which enables communication between 2 control systems of rectification from inshore and power transformer on country’s oilrigs.

Design of HVDC Light power transformer for Valhall complex is complied with 2-level bridge principle but unstable center of coupling capacitor. Movement of bridge ranging from 0 to 150 kV can provide an optimal use value for the design of HVDC coaxial cable. That method let the operation in both steady and moving state generate slight induce current. This is one of the most decisive factors to load HVDC electricity in sea environment.

While offshore equipments are operated with fixed frequency of 60Hz, inshore ones are operated with 50Hz. So, it’s no need for main circuit’s equipment to be distinctive. Designing principles for an ordinary power transmission are also applied for alternating current network in each coastal area like Valhall complex. Besides, other significant benefits of HVDC power load for floating offshore lattices are below:

- Regulation of electric pressure and alternating frequency.

- Direct and online start-up of unsynchronized generators with high capacity

- Overcome of alternating interference in the mainland.

Environmental requirements

In terms of equipment installation for floating offshore lattices, saving space and weight is of most importance. In this aspect, HVDC filters with neat design are preeminent. Other requirements as followed:

- Safety for executive workers in producing and processing environment

- High creditability and availability: it’s very important because whether an electricity interference occurs will stop the entire assembly line in Valhall complex

- Strict selection of materials and surface process as a result of rough sea environment, salt-contained air and high rate of humidity

- Synchronization of control systems: to arrange processing and on-off control systems on the same offshore lattice.

High-voltage equipments are to be installed in a module of an offshore lattice and in a building inshore. An air ventilation system is also installed in that module to protect such high-voltage and electric equipments from salty air and wetness. In this method, main circuit’s equipments have to meet less environment requirements than outdoor equipments, and therefore, can be neater in design.

The air ventilation system, first, must cover losses related to air. An advantage of coastal air area of North Sea is that cold water (5-11 degree celsius) is available for cooling process. Second, it must also consider ability of air trespassing the lattice. Space in the module is boosted in pressure against air trespassing into high-voltage area. If air is found, the on-off control system will switch.

HVDC module will be divided into 2 layers, with alternating filters and preventive phase reactors in the first layer and power transformer valves and direct current equipments in the second one. The below layer is also installed 150kV HVDC cable output. Power transformers will be placed in a separate room whose output is covered by electrical insulator through the wall to preventive phase reactors and respective 11kV alternating equipments. Alternating filters are put in two sides of the power transformer to minimize harmonic wave affecting alternating systems in offshore lattices.

The inshore power transformer will be located in Lista and connected to the Norwegian 330kV electrical network by a double-connection line towards Feda. The surface for main equipments of Lista power transformer is fundamentally the same as that of offshore lattice of Valhall complex, except for 2 differences. First, Valhall alternating current voltage is 11kV compared to 330kV that of Lista. As a result, alternating lattice will be designed as ordinary outdoor installation station in which alternating cut machine has two cuts separated so as to connect Valhall station with main bars of the lattice. Second, valves of cooling system are characterized as dry air-cooling towers.

Having the control system been compatible with each other for technology processing in offshore lattice create different creditability from normal loading system. In an area being in touch with gas, it’s more important for driven orders to cutting machine to be safe and reliable than continuous operation. So the control system is added several circuits to make driven orders outside from emergency alert system.

Software controlling power transformers will be made compatible with the potential adjusting frequency; and hardware will be identical to a rectifier and reverse power transformers. Monitoring and protecting function of the control system will also be integrated.

Minimizing harmonic waves

It’s the process of reducing weight of equipments on the lattice that brings an optimal solution to minimizing harmonic waves: the lattice is not allowed to have harmonic level exceeding the set level. Hence, the designation will be driven to installing filters with the same capacity. That is a normal requirement in installing high-voltage equipments and huge harmonic wave is not permitted.

Harmonic waves are generated from HVDC power transformers chiefly at the on-off frequency of over 1620 Hz. Harmonic waves at the 5th, 7th, 11th, 13th level are common waves in usual HVDC power transformers.